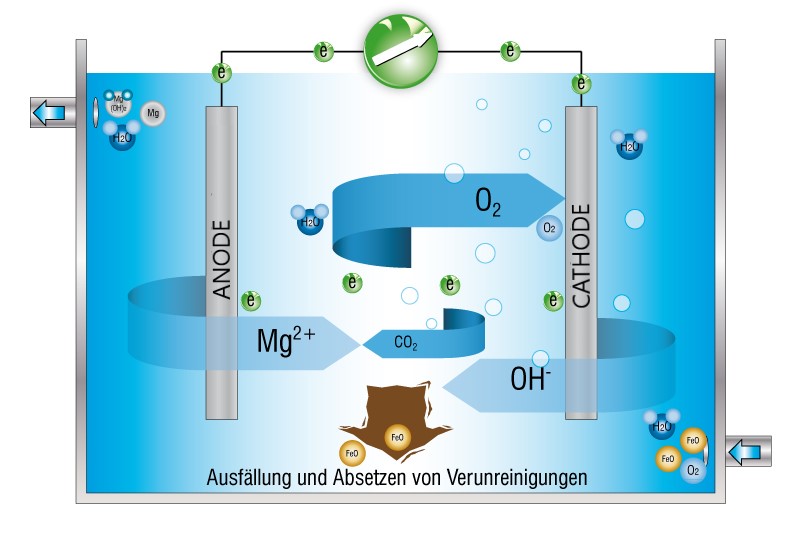

High purity magnesium anodes are fitted within every elector reaction tank and replacement anodes are available from stock in the UK to ensure that your assets remain protected against corrosion at all times. Magnesium anodes when used in conjunction with electrochemistry provide a suitable & environmentally friendly solution to ongoing constant corrosion protection without the need for harmful chemical additives.

We only use the highest quality magnesium anodes available to ensure maximum standard potential is achieved from within the electrochemical reaction chamber.

As a result, this offers superior performance of the anti-corrosion device & that the anode degradation is uniformed across the complete structure.

Our magnesium anodes far outperform regular anodes which may be found in drinking water applications as an example. The pure material composition doesn’t consist of any unwanted foreign substances which reduces the purity of the anode and in turn effect the reactions from within the reaction chamber when utilised in electrochemical water treatment.

Our anodes are designed for the most effective electrochemical water treatment possible. The consumption of the anode is the result of the activity of the electrochemical cell. This activity is determined by the so-called cell potential, which is determined, among other things, by the purity of the probe alloy.

Protection against corrosion for the complete heating/cooling systems can be achieved strictly without the use of harmful chemical. Furthermore this sustainable and environmentally friendly solution offers a significant cost reduction when compared to traditional chemical dosing.

The concentration of dissolved gases in the water and the electrical conductivity of the heating water also play a major role in the service life of the anode. Since our anodes are made of a high-purity magnesium alloy, their reactivity is particularly pronounced. Anodes with a lower magnesium content offer a longer service life, but are less active, which can have a strong influence on the rate of oxygen consumption, for example.

Our high-purity magnesium anodes have an average lifespan of 2 – 5 years. The service life can be extended if the electrical conductivity of the heating water is reduced to a level <100 µS / cm by desalination. For the best possible function of the electrochemical water treatment, we recommend changing the anode every two years, regardless of the service life of the anode.